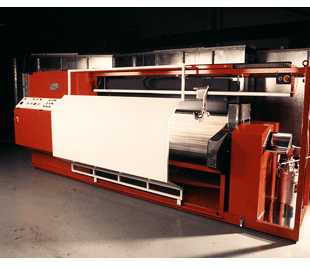

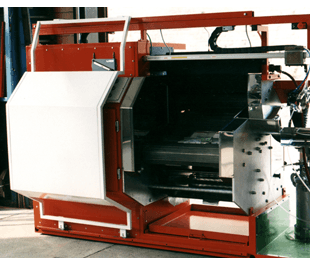

Quadrant Coater for the bulk coating of small components

Revolutionary coating machine

The revolutionary Quadrant Coater now brings an added dimension to bulk coating techniques. Greater accuracy and better surface finish on previously difficult shapes can now be coated with all the economic advantages of an automatic bulk coating technique.

Practical solutions to bulk coating methods

P & P Products Ltd are well aware of certain deficiencies of the well established dip-spin bulk coating method through our involvement in the manufacture and design of a range of dip-spin machines.

We offer you practical solutions to the bulk coating methods for both organic and inorganic coating materials.

One particular concern, has been the coating tolerances for components coated with functional coatings such as fluorocarbons used for mechanisms or threaded fasteners where fit is just as vital as the corrosion resistance.

Talk to us about assessing your requirements

With this kind of coating concept, the engineering support and back up is considered a very important ingredient to both the marketing of these machines as well as to the users once the machine is in operation. We offer you an assessment process to develop a programme to coat your specific components.

A simple automatic feed system

In principle the Quadrant Coater comprises a belt containing the components to be coated. This automatically feeds them into position' coats, dries and repositions. The cycle can then be repeated as required depending on the configuration of the component, before discharge for final cure, if required. The coating and drying cycles can be preprogrammed for each type of component and coating materials used.

Talk to us about your design and manufacturing requirements.

Call us on

01274 296 793

or

01274 918 737

| Description | QC 600 | QC 1200 |

| Height | 1600mm | 1600mm |

| Length | 2400mm +1200mm | 3310mm + 1200mm |

| Depth | 1170mm + 700mm | 1170mm + 700mm |

| Belt Width | 610mm | 1220mm |

| Lifters | 6 sets @ 500 + 550 centres | 1220 6 sets @ 500 + 550 centres |

| Working Load (approx) | 7 - 10 kg | 15 - 20 kg |

| Process Temperature (max) | 130 degC | 130 degC |

| Input Air Volume | 100 cfm filtered | 200 cfm filtered |

| Extraction High Level | 900 cfm | 1300 cfm |

| Low Level | 400 cfm | 750 cfm |

| Air Consumption (max) | 20 cfm | 20 cfm |

| Power Consumption | 12 Amps | 24 Amps |

| Heaters | 9kw | 18kw |

| Exhaust Spigot | 200 x 200 | 200 x 250 |

| Air Service Connection | 3/8 BSP | 3/8 BSP |

| Electrical Supply | 15 Amps | 30 Amps |

| Spray Gun | Devilbliss AGG 504 Auto | Devilbliss AGG 504 Auto |

| Pressure Feed | 2 Galion Pressure Pot c/w Ram Motor | 2 Galion Pressure Pot c/w Ram Motor |

| Gross Weight | 1000 kg | 1000 kg |