Why choose P & P Product's industrial box ovens?

Applications

P & P Products Ltd's ovens can be used in virtually any industry for drying, stoving, curing, baking, moisture removal, preheating etc.

Standard features, quality construction

The oven structure is formed from a rigid framework with double skinned panels infilled with a minimum 100mm thick mineral wool insulation. All interior panels are manufactured from Aluminised steel capable of withstanding up to 500°C. Exterior Zintec panels are welded in place making a very strong structure and the oven is finally painted to give an attractive, durable finish.

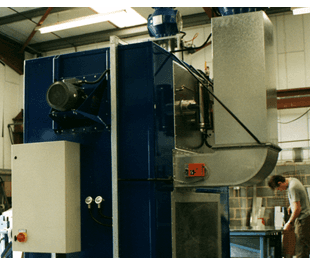

Good heat distribution

A powerful circulation fan(s) carefully matched to the oven design forces heated air rapidly across the oven ensuring uniform temperature (up to 250°C) throughout.

Comprehensive controls

A clear control panel includes a PID temperature controller with digital display of set point temperature/process temperature and high limit protection, pre-purge and cool down timers, process timer and audible alarm, status indicator lamps and on/off controls.

Exhaust damper

An adjustable damper in the roof exhaust duct controls the amount of air released to atmosphere.

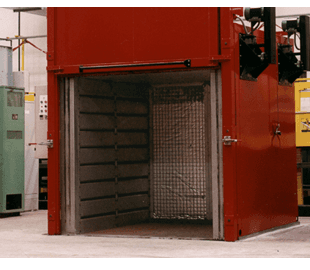

Heavy duty doors

Internal and external handles are fitted for safety and heavy duty replaceable hinges are standard.

Explosion relief

A special panel fitted to the rear wall is designed to minimise damage in the event of an explosion.

Gas or electric

P & P Products Ltd manufacture both gas and electric fired ovens to cater for all requirements.

Gas fired ovens feature a high efficiency burner from a leading manufacturer. The burner which is mounted in the oven roof incorporates failsafe protection devices and electronic ignition. As a result of the high efficiency burner, excellent insulation and very responsive controls, P & P Products Ltd gas ovens are very economical to run.

Electric ovens recirculate air over a three phase heater battery of Incoloy sheathed elements powered by a solid state thyristor drive unit. Where gas cannot be used or is not appropriate for some reason these electric ovens are the obvious choice.

All P & P Products Ltd industrial box ovens are delivered fully assembled, ready wired and tested in our works.

OPTIONAL EQUIPMENT SIZES FROM 1 m3 TO 40m3 TEMPERATURES UP TO 300°C GAS OR ELECTRIC FIRED HORIZONTAL/VERTICAL AIR FLOW

MECHANICAL EXHAUST for solvent evaporation processes

WORK TRAYS, HOLDERS & TROLLEYS INSULATED OR PLATE STEEL FLOOR

VERTICAL RISING DOORS to maximise floor space Electric ovens recirculate air over a three phase heater battery of Incoloy sheathed elements powered by a solid state thyristor drive unit. Where gas cannot be used or is not appropriate for some reason these electric ovens are the obvious choice.

All P & P Products Ltd industrial box ovens are delivered fully assembled, ready wired and tested in our works.

OPTIONAL EQUIPMENT SIZES FROM 1 m3 TO 40m3 TEMPERATURES UP TO 300°C GAS OR ELECTRIC FIRED HORIZONTAL/VERTICAL AIR FLOW

MECHANICAL EXHAUST for solvent evaporation processes

WORK TRAYS, HOLDERS & TROLLEYS INSULATED OR PLATE STEEL FLOOR

VERTICAL RISING DOORS to maximise floor space

Chart recorders of stainless steel construction painted in your choice of colour

| Height (mm) | Width (mm) | Depth (mm) | Height (mm) excluding duct | Width (mm) oven body | Depth (mm) | Gas oven burner btu's | Electric oven heater Kw | Circulation Fan Kw | Extract Volume (max) cfm |

| 1800 | 1500 | 1500 | 2500 | 2100 | 1700 | 50,000 | 15 | 1.5 | 200 |

| 1800 | 1500 | 1800 | 2500 | 2100 | 2000 | 65,000 | 21 | 1.5 | 250 |

| 2000 | 1800 | 2400 | 2700 | 2400 | 2600 | 110,000 | 30 | 2 x 1.5 | 400 |

| 2000 | 1800 | 3000 | 2700 | 2400 | 3200 | 125,000 | 36 | 2 x 2.2 | 450 |

| 2000 | 2400 | 2400 | 2700 | 3000 | 2600 | 130,000 | 39 | 2 x 2.2 | 450 |

| 2000 | 1800 | 3600 | 2700 | 2400 | 3800 | 135,000 | 42 | 2 x 2.2 | 450 |

| 2000 | 2400 | 3000 | 2700 | 3000 | 3200 | 150,000 | 42 | 2 x 3 | 600 |

| 2000 | 2400 | 3600 | 2700 | 3000 | 3800 | 175,000 | 51 | 2 x 3 | 600 |

| 2000 | 3000 | 3000 | 2700 | 3600 | 3200 | 175,000 | 51 | 2 x 3 | 600 |

| 2000 | 3000 | 4000 | 2700 | 3600 | 4200 | 220,000 | 66 | 2 x 4 | 850 |

STANDARD OVEN MAX TEMP 250°C *OPTIONAL MECHANICAL EXTRACTION

Note: Heating values w be ncleased w th Mechan ca Extiact on

P&P Products Ltd. persue a po icy of continuous product development, therefore, product dt Lai s and spec f cation may differ from those appear ng here

Talk to us about your design and manufacturing requirements.

Call us on

01274 296 793

or

01274 918 737